Not known Details About Premier Aluminum Llc

Not known Details About Premier Aluminum Llc

Blog Article

Premier Aluminum Llc Things To Know Before You Get This

Table of ContentsExcitement About Premier Aluminum LlcThe 6-Second Trick For Premier Aluminum LlcSome Known Details About Premier Aluminum Llc Our Premier Aluminum Llc Ideas

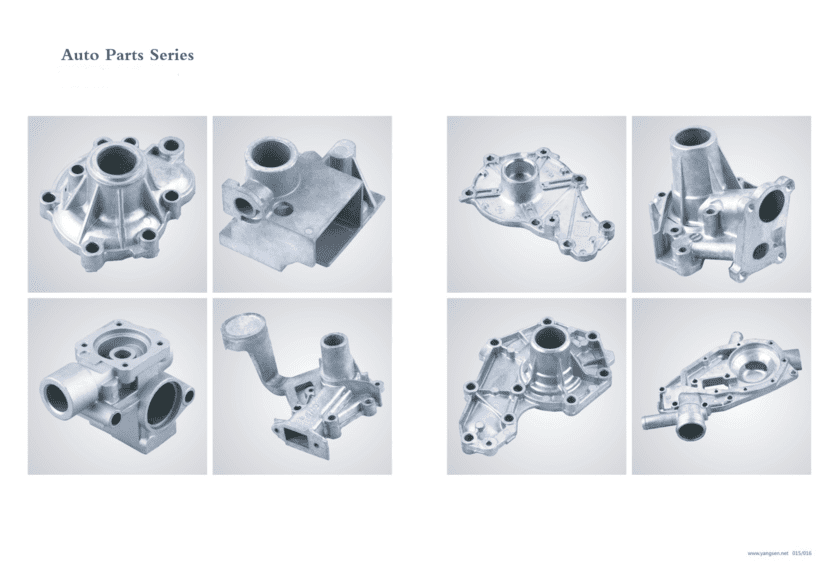

(https://anyflip.com/homepage/ujnxt)Generally, a purchaser's primary obligation was to discover certified and responsive distributors. Sometimes, purchasers presumed that any provider ready to contractually meet the purchase demand was qualified. However, utilizing reduced expense and unqualified distributors can trigger high quality concerns, and lost time and cash in the lengthy run. To help you via the procedure, below are some points to consider when picking the best metal spreading supplier.

For instance, a company that just uses the investment spreading procedure will try to market you on why that procedure is best for your application. What if utilizing the sand casting process is best for you and your needs? Rather, search for a vendor that uses a variety of casting processes so the very best choice for YOU is selected

If dealing with a solitary resource for all of your casting needs is essential to you, the provider requires to be diverse in its abilities. When incorporated with other integrated capacities, this can help simplify and compress the supply base. When choosing the ideal casting vendor, careful factor to consider ought to be given to top quality, service, and rate.

An Unbiased View of Premier Aluminum Llc

Purchasers significantly choose spreading vendors who have machining capacities. If the casting vendor uncovers a concern during machining, the trouble is settled quicker with no conflict over whose mistake it is.

Trouble or no, incorporated machining streamlines the supply chain and lowers dealing with time and delivery price read the full info here before the product makes it to the customer. What do you need from your spreading supplier? Are you searching for somebody to just deliver a steel element to your front door or do you require extra? If you do not have in-house metallurgy experience, validate that the vendor can supply advice in selecting the appropriate alloy based on your specific application.

Some foundries are restricted or specialized. Make sure the provider can meet all your product or alloy requirements to eliminate the demand for multiple vendors.

Premier Aluminum Llc for Beginners

Study the supplier's web site. Talk with a sales representative or company affiliate. Ask a great deal of inquiries. Visit their facility. Obtain an understanding of what they can do for you and if you can see yourself building a strong, common relationship with them.

Aluminum is likewise lightweight and has excellent rust resistance, making it suitable for applications where weight and sturdiness are vital variables. In addition, aluminum casting is an economical approach of production, as it calls for less power and resources than other techniques. Iron casting, on the various other hand, includes pouring liquified iron into a mold and mildew to create a preferred shape.

The 5-Second Trick For Premier Aluminum Llc

Iron casting is additionally able to endure heats, making it appropriate for use in applications such as engine parts and commercial machinery. However, iron casting can be more expensive than aluminum casting because of the greater expense of raw products and the power required to thaw the iron. When choosing between aluminum casting and iron casting, it is very important to think about the particular needs of the application.

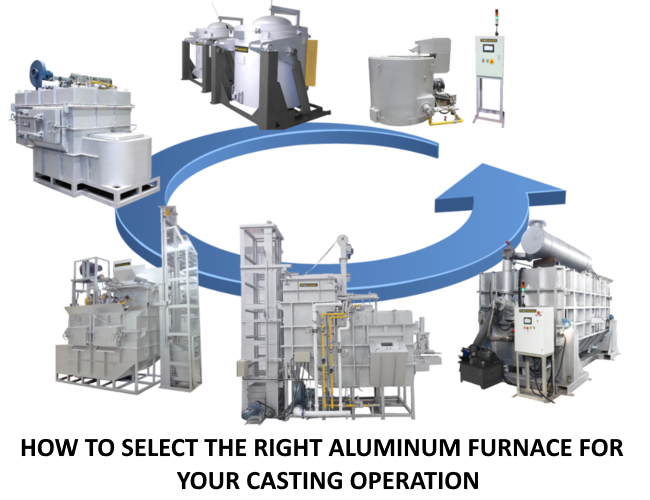

In verdict, both aluminum casting and iron spreading have their own distinct benefits and negative aspects. There are three sub-processes that drop under the group of die spreading: gravity die spreading (or permanent mold and mildew spreading), low-pressure die casting and high-pressure die spreading. To get to the ended up item, there are three key alloys used as die spreading product to select from: zinc, aluminum and magnesium. Report this page